Transcript

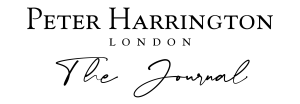

Rounding and Backing

Once the sections have been sewn together and the page edges gilded, the book block is rounded and backed. The spine is rounded with the face of the backing hammer working directly on the bench. A layer of glue, which has already been applied to the spine, ensures that the sections don’t slide against each other while the book is being worked on. The book block is placed in the backing machine so that the spine is a board thickness proud of the press edges. Starting with the middle sections and working outwards, the backing hammer claw is used to fold the spine edges of each section over the next section. The outer sections fold over the press edges to create a joint for the thickness of the boards. The metal roll is then brought over the spine several times to smooth out any irregularities ant sharpen the joints.

Trimming the Boards

The boards are measured so that they will lie a little beyond the page edges in order to give the edges some protection. They are cut to size on a board chopper.

Head-banding

The head-bands are sewn by winding three different colours of thread in a particular way around a core made from cloth and thin card. The thread is sewn, or tied down, into some of the sections in order to attach the head-band to the spine of the book. The excess core is trimmed at an angle from the edge of the head-band to the edge of the spine.

First and second linings

The linings are glued to the spine with animal glue. The spine is first lined with a strip of mull which gives a good key to the glue and ensures that the other linings are held firmly in place. A shorter and wider calico strip spine comes next and then a strip of Kraft paper. Each layer is rubbed down well with a bone folder. The extra width of calico will be used to reinforce the joints. The spine has been left to dry and sanded smooth. A hollow is made on or off the book by folding and gluing Kraft paper together to form a tube the width of the spine.

Raised Bands

The spine is divided so that the five bands will be equal distant apart from each other and the head of the spine but the tail panel will be one third larger than the others. This is done purely for aesthetic reasons. Bands are then trimmed.

Covering

The leather is cut to allow a good size turn-in all round, and pared thinner where necessary. The outer surface is damped down before applying cold water paste to the other side. The leather is wrapped around the book and worked on to the spine. It is worked firmly over the bands with a band-stick. The boards can be repositioned if necessary at this stage. The book is opened up and the corners of the leather are cut away with shallow 45 degree cut just over a board’s thickness away from the book boards. The leather at the tip is then pared very thinly using a knife so that it can be mitred neatly around the corners. The leather is turned in over the boards and down the joints and the head-caps are formed with a bone folder.

Nipping bands

The bands are made more defined with the use of band nippers.

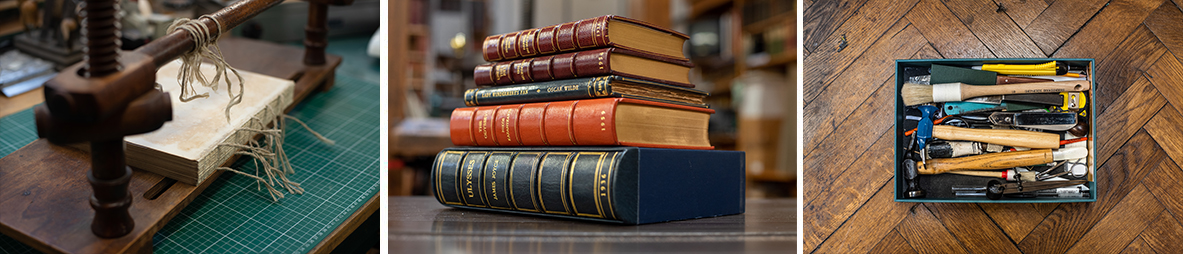

Finishing

The books are decorated with gold leaf. Glaire is applied to the leather before placing the gold on. A heated brass tool activates the glaire underneath permanently attaching a pattern of gold to the leather. Any loose gold can be cleaned off. The bindery has a variety of rolls, decorative tools and pallets. A spine is decorated with pallets and centre tools.

Using the intertype to create the lead letter type for the titles

Lead lettering slugs are made up for each individual title with the intertype machine. Once the titling is done, the lead is melted down again for the next book. This machine came from the Zaehndorf bindery and, as far as we know, is the only one left of its type in the London. The lead slugs are placed in type-holders.

Lettering the spine

These are used in the same way as the decorative tools.

Pasting down the endpapers

This is the last process to be done in order to complete the binding of a book.